PAST PROJECTS

- USCGC JAMES PSA-1 DOCKSIDE REPAIRS

- CITY OF CLE BUOY

- CITY OF ASHTABULA UNDERWATER PIPE REPAIR

- WORKBOAT SALVAGE

- INTERLAKE TIRE REMOVAL DIVE

- MANITOWOC SHELL PLATE INSERT

- FETTES CARGO HOLD CLEANING

- UMICORE FILTER PRESS STRUCTURAL FOUNDATION

- CCSR FEATURED IN CLEVELAND CRAIN’S BUSINESS WEEKLY

- ASHTABULA FIRST ENERGY PLANT “C” DIVE

- USCGC BAYBERRY 65’ DOCKSIDE REPAIRS

- USCGC ELM 225’ DOCKSIDE REPAIRS

- USACE – PITTSBURGH DISTRICT, FLOATING MOORING BITTS

- KEYLAKES PHILIP R. CLARKE EMERGENCY STEEL REPAIRS

- BARGE SLOPE MODIFICATIONS

- INTERLAKE STEAMPSHIP COMPANY BALLAST TANK REPAIRS & CLEAT FABRICATION

- ROAM ROCK ASSOCIATION BARGE CONSTRUCTION

- USACE – MEMPHIS DISTRICT, M/V WARD CUMMINS 6BT5.9M SSDG ENGINE OVERHAULS

- YACHT TRANQUILITY HYDRAULIC STEERING AND BOWTHRUSTER REPAIRS

- ANDRIE, INC. BARGE A-397 MAJOR STEEL REPAIRS

- ANDRIE, INC. TUG REBECCA LYNN FM200 SYSTEM INSTALLATION

- CITY OF TORONTO, OHIO INTAKE INSPECTIONS & REPAIRS

- DTE ENERGY ASHTABULA VALVE & PIPING REPAIRS

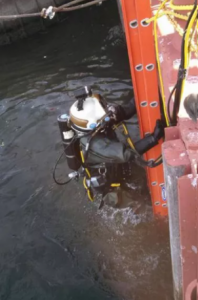

- DONJON SHIPBUILDING GRAVING DOCK GATE VALVE REPLACEMENT DIVE

- ERIE WATER WORKS PUMP CONE INSTALLATION

- FETTES SHIPPING TUG PETITE FORTE EMEGENCY REPAIRS

- DTE ENERGY ASHTABULA WATER STORAGE TANK INSULATION RENEWAL

- DTE ENERGY ASHTABULA STEAM PIPING INSULATION/SHEATHING REPLACEMENT

- JD WILLIAMSON DIVE, H-PILE REMOVAL

- EAE LOGISTICS CONVEYOR TECHNICIAN/MECHANIC

- INTERLAKE STEAMSHIP COMPANY JOHN SHERWIN WINCH REMOVAL/REBUILD

- DTE ENERGY ASHTABULA GENERATOR REPAIR & PRESERVATION

- USCGC KATMAI BAY DOCKSIDE

- PRESRITE – JEFFERSON, Ohio

- CONVEYOR REPAIR & PAINTING

- R/V GRANDON GENERATOR INSTALLATION

- M/V CALUMET ELECTRIC REPAIRS

- REPAIRS ABOARD FLAGSHIP NIAGARA LEAGUE'S BRIG NIAGARA

- FIRST GOVERNMENT AWARD: NOAA HENRY BIGELOW

- WINTERWORK

- MAID OF THE MIST CORPORATION (REPOWER)

- MAID OF THE MIST CORPORATION (NAVIGATION LIGHTS)

- MAID OF THE MIST CORPORATION (DECK LIGHTING)

- MAID OF THE MIST CORPORATION (BARGE ROOF MODIFICATION)

- GRAND RIVER NAVIGATION MANITOWOC

- GRAND RIVER NAVIGATION TUG DEFIANCE/BARGE ASHTABULA

- INLAND LAKES MANAGEMENT ALPENA

- FETTES SHIPPING TUG PETITE FORTE/BARGE ST. MARY'S CEMENT

- UNITED STATES NAVY PIER STANDS

- UNITED STATES COAST GUARD PAINT FLOAT

- FEATURED IN STAR BEACON, WORK BOAT, and MARINE LOG FOR RE-POWER Star Beacon

- TANK FABRICATION

- USCGC JAMES PSA-1 DOCKSIDE REPAIRS

- USCGC JAMES PSA-1 DOCKSIDE REPAIRS

- 2015/16 Winterwork

- Calumet Hatch Crane Engine Replacement

- USCGC Hamilton WMSL 753 Dockside Repairs

- Herbert C. Jackson Generator Removal/Re-Installation

- USACE Cheraw Window System

- USACE Donlon Navigation System Upgrades

- Winter Work 2020: Barge Ashtabula & Tug Defiance

- Winter Work 2020: Barge Menominee & Tug Olive L. Moore

- Winter Work 2020: M/V Calumet

- Winter Work 2020: M/V Robert S. Pierson

- Winter Work 2020: M/V Cuyahoga

- Winter Work 2020: M/V Mississagi

- Winter Work 2020: M/V Saginaw

- Winter Work 2020: M/V Ojibway

- Miller Ferry Steel Repair

- M/V Calumet Port Main Diesel Engine Replacement

USCGC JAMES PSA-1 DOCKSIDE REPAIRS

CCSR (previously LESR) Completed the PSA-1 dockside repairs on the USCGC James in Charleston, SC. The project started September 15th, 2015 and was wrapped up by November 17th, 2015. Projects included fire system maintenance, deck covering renewal, wardroom equipment renewal, modifications to starboard boat davit, mission module to stateroom conversion, and several other miscellaneous tasks.

Side repairs on USCGC Hamilton in Charleston, South Carolina. Repairs included tank cleaning,fire system certification, flight deck net testing and inspection, deck preservation and tank preservation.

CCSR (previously LESR) was contracted to renew a damaged section of shell plate on the M/V Manitowoc. The repair consisted of cropping and renewing a 8’ x 12’ section of 5/8” plate. The repair was completed in four days with crews working around the clock to get the vessel back into service. Upon completion repairs were tested and certified by USCG and Lloyds Register.

CCSR (previously LESR) has an ongoing contract for Fettes Shipping to perform cargo hold cleaning operations on their vessels in Cleveland and Toledo when cargo type is changed. This consists of lowering skid steers into the cargo hold with a crane and removing all material to prepare the vessel for cargo change.

CCSR (previously LESR) was featured in the February 3-9, 2014 issue of Cleveland Crain’s Business Weekly. The article was written about the early success of the father-son tandem management team at CCSR . Crain’s was onsite as the CCSR dive team did an underwater hull inspection and survey on the dinner cruise vessel Nautica Queen located in Cleveland, Ohio. CCSR provided a live audio/video feed so that the inspectors from The United States Coast Guard could visually inspect the vessel from shore.

CCSR (previously LESR) completed a 45 day dockside availability in Oak Island, NC onboard the 65’ United States Coast Guard Cutter Bayberry. Work Items included: Forward peak preservation and inspection, buoy crane overhaul, ventilation fan repair, interior “terrazzo” deck covering renewal, hull and structural plating replacement, pilothouse top and mast repairs, airport and fixed light overhaul, and tank cleaning.

CCSR (previously LESR) completed a 60 day dockside availability in Atlantic Beach, NC onboard the 225’ United States Coast Guard Cutter Elm. Work Items included: buoy and cargo crane overhaul, commissary hoist repairs, grey water and sewage system cleaning, interior “terrazzo” deck covering renewals, crane hydraulic swivel replacement, tank cleaning, SSDG cleaning and inspection, hose reel overhaul including fabrication of new hose reel frame, and forward mast repairs.

In May of 2016, CCSR (previously LESR) entered into an exclusive manufacturing agreement with service tanks of Louisville, KY. We are taking over all tank manufacturing operations and have moved into a new 140,000 square foot shop to support our expansion. In addition, we have acquired a large amount of new welding and fabrication equipment to support tank and other heavy fabrication. Take a look at the fabrication tab to view our new equipment! We have added 20+ new employees.

Side repairs on USCGC Hamilton in Charleston, South Carolina. Repairs included tank cleaning,fire system certification, flight deck net testing and inspection, deck preservation and tank preservation.

During the winter of 2015/16, we completed top side repairs on the M/V Manitowoc, Tug Defiance and Barge Ashtabula, and Tug Rebecca Lynn and Barge A-397. All three projects were a success! Work included: steel renewals, fire main washdown line, machining, gate repairs, fall arrest system installation, boom cable renewal, bow thruster replacement and refurb and numerous other projects!

Terlake’s Herbert C. jackson which included providing underway repairs from the loading port of Cedarville, Michigan to the discharge Muskegon, Michigan to rig and remove a generator that required repair. The generator was repaired on-shore and CCSR crews went aboard the vessel again to final testing resulting in a favorable outcome.

CCSR was contracted to remove a crawler crane off of a government barge, and build a new foundation for the new crane. This took around 9 months to complete in Ashtabula Ohio. The foundation for this crane was 1-”-thick steel.

During the winter layup season of 2017/2018, CCSR completed dockside repairs on the M/V Calumet. The main focus on this vessel was replacing the incline belt catch funnel, replacing 3 fluid drives and some small inserts around the pilot house.

During the winter layup season of 2017/2018, CCSR completed dockside repairs on the Barge Menominee and Tug Olive Moore. The main focus of this barge was replacing 240 ‘of 12-” ballast piping and a 72 -’ by 12-’ insert in cargo hold # 1.

During the winter layup season of 2017/2018, CCSR completed dockside repairs on the M/V Mississagi. Some of the main jobs on this vessel were sealing any leaking rivet, renewing 100 ‘of tunnel skirt boards, and renewing 250 ‘ of the tunnel belt structure.

CCSR was contracted to assess and repair a barge that had significant barge damage due to a collision. Over 48,000 lbs. of steel were renewed on the vessel in Detroit, MI during the 2018/2019 winter season. The repair included a 45’ x 16’ x ½” side shell insert as well as longitudinal, transverse framing, and bulkhead renewal.

CCSR was contracted to design, fabricate, and install a new floor for an industrial bulk material distributor’s sand dryer. This structure was built using RA2507, a high heat stainless steel, and installed in the dryer approximately 20 ‘off of ground level.

During the winter layup season of 2018/2019, CCSR completed dockside repairs on the Barge Ashtabula & Tug Defiance. Work included ABS determined ballast tank repairs, cargo hold crack repairs, miscellaneous deck equipment upkeep, and bearing renewals for various belt rollers.

During the winter layup season of 2018/2019, CCSR completed dockside repairs on the Barge Menominee & Tug Olive L. Moore. The main job was a 15’ x 30’ x ½” side shell insert at #4 STBD Ballast tank where the vessel was previously damaged. Additional work included ABS determined ballast tank repairs, cargo hold gate renewals & repairs, and other miscellaneous steel repairs.

During the winter layup season of 2018/2019, CCSR completed dockside repairs on the M/V Calumet. Work included ABS determined ballast tank repairs, various piping throughout the vessel, steering gear bearing replacements, grocery hoist renewal, and an 8’ x 15’ side shell & frame insert in the generator room.

During the winter layup season of 2018/2019, CCSR completed dockside repairs on the M/V Mississagi. Work included ABS determined ballast tank repairs, [2] tunnel motor overhaul assists, and elevator & conveyor steel repairs.

During the winter layup season of 2018/2019, CCSR completed dockside repairs on the M/V Saginaw. The main job was a complete renewal of screen bulkhead #4/5, and renewal of all outer slope plate in cargo hold #6. Work included ABS determined ballast tank repairs, renewal of ballast expansion couplings, bucket elevator repairs, and other miscellaneous steel renewals.

CCSR was contracted to fabricate, furnish, and commission a small 16’ wide x 25’ long truck-able push workboat. The owner provided a small unfinished hull, which had to be overhauled, and then fabricated an engine room overhead space, as well as a pilot house. CCSR also installed and aligned the engines, fabricated and installed the rudders & steering system, ran all hydraulic, fuel, oil, & water piping, ran all electrical for the vessel, and fabricated all deck equipment. CCSR also blasted & painted the entire vessel.

CCSR was contracted to fabricate, and deliver, over 600 linear feet of double channel waler to a construction company renewing the dock face/sheet piling at Bradstreet Waterfront in Rocky River.

CCSR has been fabricating cargo hold hatch covers for various vessels over the past few years. Currently, CCSR has built covers for the following vessels: M/V Cuyahoga, M/V Robert S. Pierson, M/V Calumet, and M/V Manitowoc. All covers are built to an approved drawing and verified throughout the process by either ABS or Lloyd’s register. After fabrication, covers are blasted & painted, and have their gasket installed before being delivered to the vessel.

During the winter layup season of 2019/2020, CCSR completed dockside repairs on the Barge Ashtabula. Some of the jobs included renewing 200‘of hydraulic piping, replacing 10 gate rams, and helping replace the tunnel belt. The main focus for this boat was slope renewal.

During the winter layup season of 2019/2020, CCSR completed dockside repairs on the Barge Menominee and Tug Olive Moore. The main work for this winter was the completed renewal of cargo hold bulkhead #1/2, as well as 900’ of 12” ballast piping renewals in #4 ballast tanks port & starboard.

The vessel also required the removal and re-installation of a ship service generator for overhaul. The additional work included the a joinery overhaul of the barge’s lounge area, ABS determined ballast tank repairs, and various gate & steel repairs

During the winter layup season of 2019/2020, CCSR completed dockside repairs on the M/V Calumet. The main work for this winter was the completed renewal of cargo hold bulkhead #1/2, as well as slope renewals and painting of hold #1. The vessel also required significant Teflon repairs across all cargo holds. The additional work included the removal & renewal of a ballast pump, ABS determined ballast tank repairs, and other miscellaneous steel & piping jobs.

During the winter layup season of 2019/2020, CCSR completed dockside repairs on the M/V Robert S. Pierson. The main work for this vessel was assistance with the removal of the port main engine crankshaft replacement and repairs on the 1/2 & 2/3 screen bulkhead repairs. Some additional jobs included cargo hold frames & arches, ballast repairs, and other various steel repairs.

During the winter layup season of 2019/2020, CCSR completed dockside repairs on the M/V Cuyahoga. The major work included removing the main engine gear box which required using a 225 ton crane to lift the gearbox from the bottom of the engine room. It also included an overhaul of the main gear pulley on the bucket elevator and an extensive list of ballast tank repairs. Some additional jobs included various piping repairs, assistance with the boom belt, and miscellaneous steel repairs.

During the winter layup season of 2019/2020, CCSR completed dockside repairs on the M/V Mississagi. The main work for this vessel included complete renewal of the upper and lower wear plate. Some additional work includes tunnel conveyor belt steel renewals, bulkhead doublers & renewals, and ABS determined ITSS survey repairs.

During the winter layup season of 2019/2020, CCSR completed dockside repairs on the M/V Saginaw. The main work for this vessel was the complete renewal of slope plating in cargo hold #5, and a crack in the STBD side shell. The additional work included various grating in ballast tanks, extensive steel renewal of ballast tank steel, as well as other miscellaneous steel repairs.

During the winter layup season of 2019/2020, CCSR completed dockside repairs on the M/V Ojibway, with the vessel arriving in late March. The vessel required approximately 50,000 lbs. of steel to be completed within two weeks of the vessel arriving. CCSR was able to finish the repairs and get the vessel out before the provided time frame

CCSR was contracted to renew wasted steel around the fuel tank of a ferry. CCSR also took UT readings to determine the wasted steel locations.

CCSR was contracted to remove and install the Port main engine. This job required CCSR to cut an 8 ‘by 8 ‘insert in the side shell to remove the engine. CCSR had to raise the engine up two levels and to the port side of the vessel with chain falls. This job took 5 days working [2] 12 hour shifts to complete.

During the winter layup season of 2020/2021, CCSR completed dockside repairs on the Barge Ashtabula and Tug Defiance. The main work included removal of teflon in cargo holds #3 and #4, as well as slope repairs in both of these holds. Additional work included ballast tank repairs, repairs on the ATB pinning system, and fabrication of a boom crane on the tug.

During the winter layup season of 2020/2021, CCSR completed dockside repairs on the Barge Menominee and Tug Olive Moore. The main focus of this barge was replacing 960 ‘of 12-” ballast piping and a 72 -’ by 12-’ insert. Some of the other jobs were renewing 80 ‘of 4 “pipe for the dredge pump renewing a cross over and placing new winches on the barge.

During the winter layup season of 2020/2021, CCSR completed dockside repairs on the M/V Calumet. The majority of the work came with the complete replacement of [2] cargo hold bulkheads, and strengthening all cargo hold hatch covers aboard the vessel. Additional work included installing a new ballast pump, installing 2 new winches and renewing the crank shaft of the main engine.

During the winter layup season of 2020/2021, CCSR completed dockside repairs on the M/V Manitowoc Work included owner’s representative determined ballast tank, strengthening/adding stiffeners to all cargo hold hatch covers on the vessel, and other miscellaneous steel renewals.

During the winter layup season of 2020/2021, CCSR completed dockside repairs on the M/V Indiana Harbor, one of the few thousand footers on the Great Lakes. The main job was a blast & paint slopes in [2] cargo holds so that ¼” wear plate could be installed (approximately 180,000 lbs.). The vessel also required installation of angle panel breakers within a ballast tank. Additional work included owner’s representative determined ballast tank and cargo hold repairs, and other miscellaneous steel renewals.

During the winter layup season of 2020/2021, CCSR completed dockside repairs on the M/V H. L. White Work included owner’s representative determined ballast tank and cargo hold repairs, and other miscellaneous steel renewals.

CCSR has an ongoing contract to perform cargo hold cleaning operations on several vessels in Cleveland, Toledo, and Detroit. This is needed when the bulk cargo material type is changed. This consists of lowering skid steers into the cargo hold with a crane, and removing all excess material to prepare the vessel for the new cargo.

The M/V Saginaw was brought to Ashtabula for some bow side shell damage. CCSR worked [2] 12 hour shifts around the clock for 7 days to replace approximately 24,000 lbs. of side shell and internal structure. The insert was 28’ x 15’ x ¾” in the #1 Port Ballast tank. ABS was onsite to sign off after the renewal was completed.

CCSR (previously LESR) fabricated (4) steel floating mooring bitts that are 26 long and are supported by HDPE pontoons that will be used in the New Cumberland Lock and Dam in Southern Ohio. FMBs were fabricated at our Ashtabula fabrication shop.

CCSR (previously LESR) was dispatched for an emergency repair which consisted of a large crack in the bow and associated stringers and stiffeners of Keylakes’ Phillip R. Clarke in the presence of the United States Coast Guard and American Bureau of Shipping inspectors which was docked in Ashtabula, Ohio.

CCSR (previously LESR) designed and built (2) 40 x 12 spud barges that pin together to form a dredging platform that will support an excavator and (2) 24 x 12 hopper barges to dispose of dredge material in our Ashtabula fabrication facility. These barges will be used for a mechanical dredging operation on Lake Roaming Rock in Rome, Ohio.

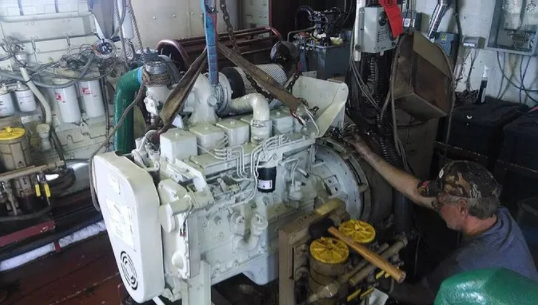

CCSR (previously LESR) was awarded the contract to remove (2) Cummins 6BT5.9M marine generator engines from the M/V Ward in Memphis, Tennessee and perform an overhaul. CCSR brought the engines to our shop and performed a complete overhaul on them including new short block assemblies, returning them to factory new condition. Once complete, the engines were hauled back to Memphis and reinstalled in the vessel.

CCSR (previously LESR) installed all piping, foundations, and accessories for a new Fireboy FM-200 fire suppression system onboard Andrie’s Tug Rebecca Lynn in River Rouge, MI.

CCSR (previously LESR) dive team was dispatched to inspect the intake at the City of Toronto water treatment facility. The plant was having intake flow issues and we were able to dive and determine that a main suction line was damaged. Repairs and modifications were made to the suction piping and CCSR installed a protective device over the new piping to prevent damage and loss of suction in the future.

CCSR (previously LESR) responded to an emergency call-out in Cleveland Ohio to repair a camshaft – fuel pump hold down on the #8 cylinder of the starboard main engine on Fettes Shipping’s Tug Petite Forte. CCSR removed, repaired, and replaced the fuel pump hold down within hours. CCSR provided a HVAC subcontractor to repair walk-in coolers. Additionally, while onsite CCSR inspected the ballast tank piping for leaks.

CCSR (previously LESR) excavated a trench for access to existing steam piping that runs between DTE and Crystal Global’s Millennium facility in Ashtabula, Ohio. Old sheathing and insulation leaked so it was removed and new insulation and sheathing was installed. Additionally, CCSR replaced a link seal that was leaking.

CCSR (previously LESR) was dispatched by JD Williamson Construction to remove old h-pile after the construction of a new bridge over Callender road in Rome, Ohio. The contractor was unable to remove two of the remaining h-pile bridge supports from shore. CCSR divers entered the river with a Broco magnesium underwater cutting torch and were able to remove the h-pile quickly and efficiently.

Our mobile service traveled to Detour Village, Michigan to complete a winch removal project onboard the John Sherwin. We also rebuilt and overhauled the winch. We had to move the winch from underneath the canopy out onto the hatch cover and move it to the edge to be removed by crane onto a barge then onto our trailer.

This work at DTE Energy in Ashtabula included structural steel repairs and blasting/painting to their emergency generator enclosure. Above are before and after shots of the project.

We were awarded the dockside availability onboard the Katmai Bay. This included electrical work, hydraulic inspections and repairs, structural inspection and repairs, exhaust cleaning, painting, crane repairs, and capstan inspection and repairs.

Presrite Corporation required steel repairs and pressure testing on (2) air receivers. There were several inserts that were required prior to testing.

Steel and hydraulic repairs were completed on this conveyor. After completion of those repairs, we repainted the conveyor in Erie, PA.

We were contracted to bring the Consilium Marine fire detection system onboard the Flagship Niagara into compliance. This project went extremely well and it put the vessel into compliance with the new USCG Chapter M regulations. We have the capability to provide complete Chapter M compliance for your vessels. New requirements include Safety equipment, Fire protection, and Machinery & Electrical System improvements. In addition, we fabricated new exhaust piping for the vessel.

CCSR (previously LESR) works years round. Winter work projects include the S/S Alpena, Tug Rebecca Lynn, and Barge A-397.

CCSR (previously LESR) performed a repower of the Maid of the Mist VI. The repower included replacing two Volvo TAMD122A Diesel engines with two Volvo Penta D13 Tier 3 compliant turbocharged Diesel engines, replacing two Twin Disc MG514C transmissions with two MGX5114DC transmissions, and replacing the old keel coolers with new Duramax Marine Duracoolers. This job was especially challenging because of the location of the Maid of the Mist’s drydock facility. The only access to the site is a 10′ x 6′ elevator with 4′ wide doors.”

CCSR (previously LESR) has completed the installation of a navigation light system and all new Perko Marine navigation lights on board the Maid VI and Maid VII. The Navigation lights were one of several projects that CCSR completed this winter that will enable the Maid vessels to operate at night. “

CCSR (previously LESR) installed emergency lighting and soft lighting on board the Maid VI and Maid VII to provide illumination of the decks. The emergency lighting will turn on in the event of a power loss, and the soft lighting will be turned on at night when the Maid vessels go out for fireworks cruises.”

CCSR (previously LESR) was contracted by the Maid of the Mist to remove the existing roof from their loading barge and replace it with a fiberglass grating deck. Adding this upper deck will allow the Maid of the Mist to load the vessels on both the main deck and the upper deck at the same time. The Maid of the Mist Corporation hopes that this modification will speed up loading times and reduce the amount of time their customers have to wait to board the vessels. In addition to adding a second deck CCSR also installed a crane pedestal and elevator support frame that the Maid of the Mist will be installing a knuckle boom crane and handicap elevator on, respectively.

CCSR (previously LESR) was awarded all of the winter work on board the Manitowoc this winter including the replacement of a MSD holding tank, cargo hold steel replacement, tile replacement, engine and generator overhauls, various piping system renewals, winch inspections and overhauls, rudder and propeller inspections, insulation resistance testing, switchboard cleaning, and many others.

CCSR (previously LESR) completed winter work on the tug Defiance and barge Ashtabula this winter including steel repairs in the cargo holds and unloading tunnel, material handling services for the blast and paint contractor, teflon plate renewal, tank vent piping renewal, exhaust lagging renewal, assistance for the contractor renewing the unloading belt, insulation resistance testing, shaft repair, and various other repair and replacement activities.

Forepeak & Ballast tank steel repairs, M/E cooler remove, repair & re-install, Raw water piping repairs, new deck and engine room lighting, new engine room distribution panels, CAT 3512 cooler replacement & piping modifications, port & stbd gearbox piping modifications, fuel transfer piping modifications, Port/STBD fairlead rebuild, New anchor windlass wearplate installation, New dezurik butterfly valves, fuel hose testing.

CCSR (previously LESR) was awarded a contract from the US Navy for three aluminum pier stands will roll away stairs. The pier stands were delivered to Bremerton Washington.

CCSR (previously LESR) was awarded a contract from the US Coast Guard to fabricate, deliver, and install an aluminum three tier paint float in Virginia Beach VA.

CCSR (previously LESR) was awarded a contract from the US Coast Guard to fabricate, deliver, and install an aluminum three tier paint float in Virginia Beach VA.

CCSR (previously LESR) provided 12 men for 6 weeks to complete numerous steel repairs in the presence of United States Coast Guard and American Bureau of Shipping onboard the Barge A-397 in River Rouge, MI.

CCSR (previously LESR) completed the removal of the existing hatch crane engine and the installation of a new John Deere 4045TF285 99HP Marine Auxiliary Power Unit. The new engine is EPA Tier 111 Compliant and powers a denison T6D Hydraulic Pump that provides the fluid power to operate the hatch crane system on board the Calument. CCSR also completed a full hydraulic system assessment and fine tuned the system to operate as effectively as possible.

CCSR (previously LESR) was contracted by the US Army Corps of Engineers to provide and install a window wiper system on 5 windows. Decca wipers were chosen for the application and CCSR completed the installation in just under two weeks. The installation required the modification of the brow around the pilothouse to make way for the side window wipers and the installation of a panel to house the power supplies.

CCSR (previously LESR) was contracted by the US Army Corps of Engineers to provide and install a new Furuno DRS4A Radar System, FA150 AIS Transponder, TZT14 Chartplotter, and a Furuno 1835 Radar System as a backup. The installations were completed in approximately 5 days and were fully integrated with all existing transponders, GPS systems and depth sounders.